Low-Activity Waste (LAW) Vitrification Facility

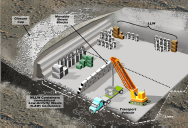

The Low-Activity Waste Facility is where the vitrification process will occur as waste is received from the Hanford Tank Farms then processed and transformed into an immobilized form safe for storage.

The Low-Activity Waste Facility is where the vitrification process will occur as waste is received from the Hanford Tank Farms then processed and transformed into an immobilized form safe for storage.

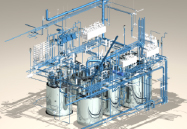

In the LAW Facility, concentrated low-activity waste will be mixed with silica and other glass-forming materials. The mixture will be fed into the LAW’s two melters and heated to 2,100 degrees Fahrenheit. The 300-ton melters are approximately 20 feet by 30 feet and 16 feet high, and, when completed, will be the largest waste glass melters in the world. The glass mixture will then be poured into stainless steel containers, which are 4 feet in diameter, 7 feet tall and weigh more than 7 tons.

The facility is 330 feet long and 240 feet wide, approximately the size of one and a half football fields, and 90 feet, or seven stories, high.

The low-activity waste containers will be stored on the Hanford Site in permitted trenches and covered with soil. The facility will annually produce approximately 1,100 containers.

CONSTRUCTION FACTS

- Size: 330 feet by 240 feet by 90 feet tall

- Concrete: 28,500 cubic yards

- Structural steel: 6,200 tons

- Heating and ventilation ductwork: 943,500 pounds

- Piping: 103,000 linear feet

- Electrical cable: 843,000 feet

Read more about Vit Plant in the Hanford Vit Plant overview.

A Closer Look Inside the Low-Activity Waste Vitrification Facility

ANNEX / CONTROL ROOM

In August 2019, Vit Plant commissioning workers moved into the 20,000-square foot, two-story annex housing the plant’s control room at the Low-Activity Waste (LAW) Facility. The annex is key to controlling Direct-Feed Low-Activity Waste operations and gives workers the capability to monitor and control completed systems inside the 14 support buildings called the Balance of Facilities. The control room will also be used to conduct startup and testing activities for the LAW Facility and Analytical Laboratory.

In August 2019, Vit Plant commissioning workers moved into the 20,000-square foot, two-story annex housing the plant’s control room at the Low-Activity Waste (LAW) Facility. The annex is key to controlling Direct-Feed Low-Activity Waste operations and gives workers the capability to monitor and control completed systems inside the 14 support buildings called the Balance of Facilities. The control room will also be used to conduct startup and testing activities for the LAW Facility and Analytical Laboratory.

PROCESS CELL

The process cell consists of six large stainless steel vessels: three for feeding waste to two low-activity waste melters and three for treating the melters’ offgas. The concentrate receipt vessel receives waste feed; a melter feed preparation vessel mixes the waste feed with glass formers; and another melter feed vessel supplies the mixed waste feed to the melters. The three offgas treatment vessels are a submerged bed scrubber to cool melter offgas and remove large particulates, a wet electrostatic precipitator to remove finer particulate, and a submerged bed scrubber condensate vessel to store and re-circulate liquid between a scrubber and the vessel.

The process cell consists of six large stainless steel vessels: three for feeding waste to two low-activity waste melters and three for treating the melters’ offgas. The concentrate receipt vessel receives waste feed; a melter feed preparation vessel mixes the waste feed with glass formers; and another melter feed vessel supplies the mixed waste feed to the melters. The three offgas treatment vessels are a submerged bed scrubber to cool melter offgas and remove large particulates, a wet electrostatic precipitator to remove finer particulate, and a submerged bed scrubber condensate vessel to store and re-circulate liquid between a scrubber and the vessel.

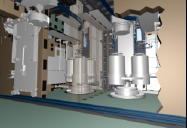

POUR CAVE TURNTABLES AND ELEVATORS

Each low-activity waste melter has two pour spouts leading down to a pour cave with two turntables and elevators. Each turntable has positions for three low-activity waste containers. An elevator raises a container under the melter pour spout. Once filled with glass, the container is lowered to the turntable and rotated to the second position to cool. The third position is for removal of the filled, cooled container and replacement with a new empty container.

Each low-activity waste melter has two pour spouts leading down to a pour cave with two turntables and elevators. Each turntable has positions for three low-activity waste containers. An elevator raises a container under the melter pour spout. Once filled with glass, the container is lowered to the turntable and rotated to the second position to cool. The third position is for removal of the filled, cooled container and replacement with a new empty container.

PRODUCTION AND OPERATIONS

The LAW Facility will contain two identical melters that will produce a sturdy glass product consisting of about 20 percent waste and 80 percent additives. The 300-ton melters are nearly five times larger than the 65-ton melter in operation at the Department of Energy Savannah River Site's Defense Waste Processing Facility in South Carolina.

The LAW Facility will contain two identical melters that will produce a sturdy glass product consisting of about 20 percent waste and 80 percent additives. The 300-ton melters are nearly five times larger than the 65-ton melter in operation at the Department of Energy Savannah River Site's Defense Waste Processing Facility in South Carolina.